If the 50s and 70s were the golden age of concrete buildings, today brutalist architecture is well and truly a thing of the past. Ever more surprising and innovative modern architecture proposes to forget closed spaces and open up buildings to their environment. Only one watchword for today’s architecture: let the sunshine in!

INNOVATION AT THE SERVICE OF MODERN ARCHITECTURE

Futuristic silhouettes, perfect balance, high energy performance: in architecture, innovation has its place at all levels, from the materials used, to how they are installed, to the maintenance of the finished building.

Today, it is in laboratories from all over the world that the materials of tomorrow are designed by engineers, that will allow us to build stronger, more beautiful and more environmentally friendly buildings.

It is these innovations in particular that have made it possible to make more room for light in modern architectural constructions. Translucent and lightweight materials are stronger and provide better thermal comfort and can therefore be more widely used. Thick walls devoid of openings in order to keep in the heat are out, breezy, clear and insulating materials are in!

WHAT’S ETFE?

ETFE or ethylene tetrafluoroethylene is a material which appeared in 1970 and which, thanks to its impressive properties, has been used in many exceptional structures.

ETFE is semi-crystalline and can therefore replace glass. But this material doesn’t just replace glass. In many ways, it’s a much better alternative:

- ETFE is cheaper than glass;

- It lets light through bettere ;

- It’s lighter ;

- It can be used in extreme temperatures from -80 degrees to over 150 degrees ;

- And just like glass, it’s recyclable.

Today, many buildings in France use ETFE to cover their structures. This is, for example, the case of the Nuage in Montpellier created by Phillipe Starck, of the Confluence shopping centre roof in Lyon or the Allianz Riviera stadium in Nice.

Other examples of buildings using ETFE internationally include the Eden Project domes in England and the Beijing Water Cube.

TEXTILE ARCHITECTURE: UNPARALLELED ARCHITECTURAL AND TECHNICAL QUALITIES

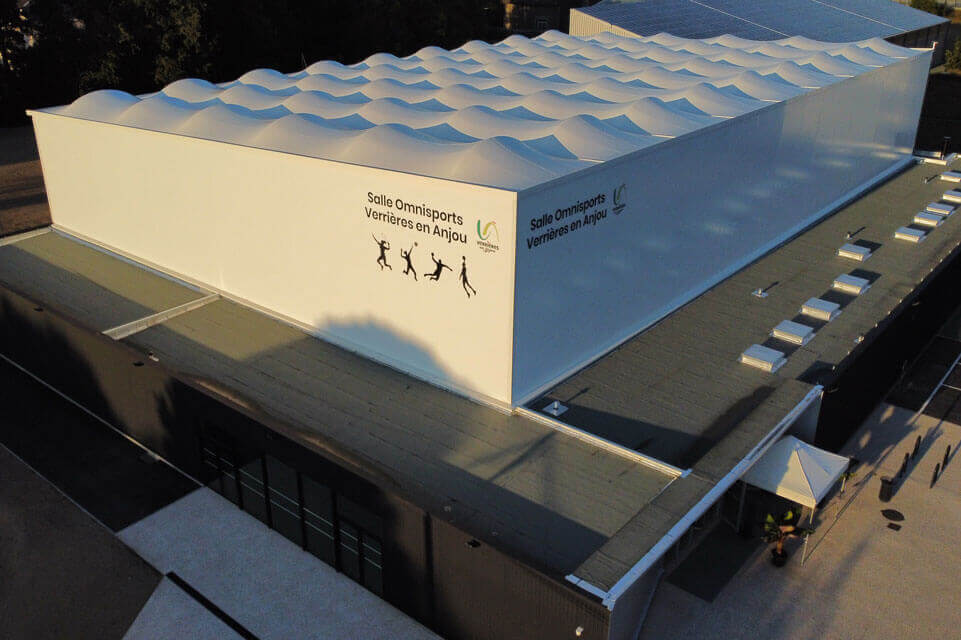

Textile architecture refers to constructions that use a textile membrane supported by a metal or timber structure, for example textile facades or textile roofs.

It’s a very fashionable technique in contemporary architecture, particularly in the world of sports: many stadiums, such as in Munich, a pioneer in the field, or the Olympic stadium in Berlin, use this technique.

Flexible and lightweight, textile membranes are compatible with all architectural audacities. They dress buildings in a breezy sail covered in surprising and minimalist geometric forms.

If textile architecture is so popular throughout the world, it’s also thanks to its technical performances, which allow it to replace more classical architectures:

- Natural daylight: Textile membranes are translucent, naturally letting light into the structure. The result? Artificial lighting is reduced in favour of pleasant light with no shadows and an average of 800 lux all year round.

- Thermal and acoustic comfort: Low thermal inertia and sound-absorbing curves allow textile architecture to guarantee a temperate atmosphere and low acoustic reverberation.

- High environmental quality: Textile architecture therefore brings natural light and controlled temperature to equipped buildings. Two qualities that reduce lighting and heating costs. Furthermore, textile membranes are 100% recyclable.

- Reduced costs: Choosing textile architecture also means saving money. Compared to a project using “classic” materials, the use of textile membranes often makes it possible to create structures at a lower cost.

It is therefore not a coincidence that textile facades and textile coverings are popping up everywhere in France and elsewhere: they have very convincing features!

Want more information? Feel free to contact us to discuss and chat with SMC2 experts about textile architecture or anything else that may concern your project.

![[TESTIMONIAL] ERIC MICHAUD, VERRIERES-EN-ANJOU (FRANCE)](https://www.smc2-construction.us/wp-content/uploads/2022/02/Verrieres_Anjou_DSC07586.jpg)

![[TESTIMONIAL] PIERRE OGOR, MAYOR OF GUILERS (29)](https://www.smc2-construction.us/wp-content/uploads/2021/10/Guilers-athletisme-1.jpg)