« [An] innovative, economical and sustainable project [that] makes our association, the city of Griesheim and the district of Darmstadt-Dieburg pioneers in sports infrastructure development! »

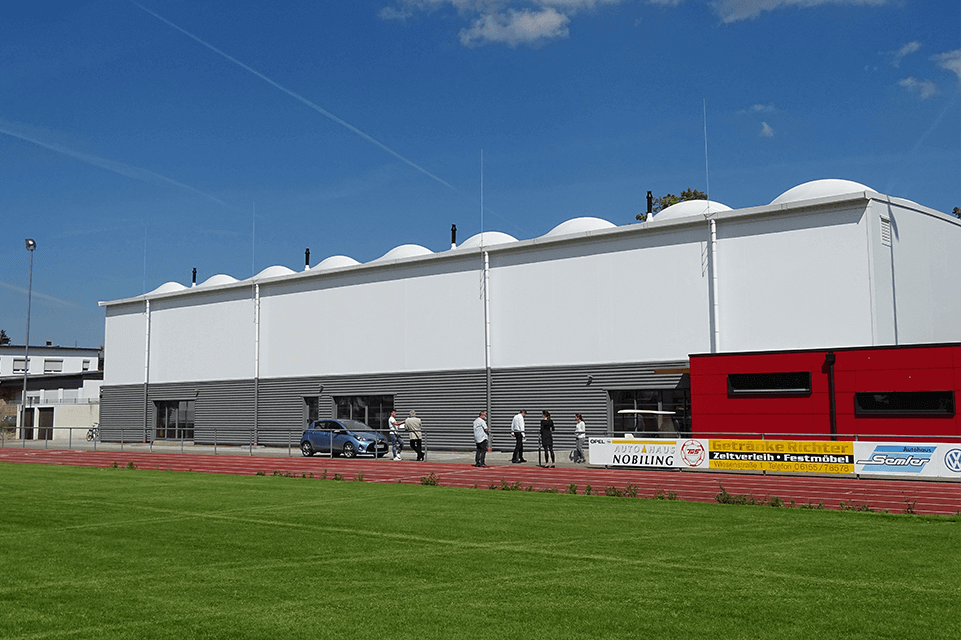

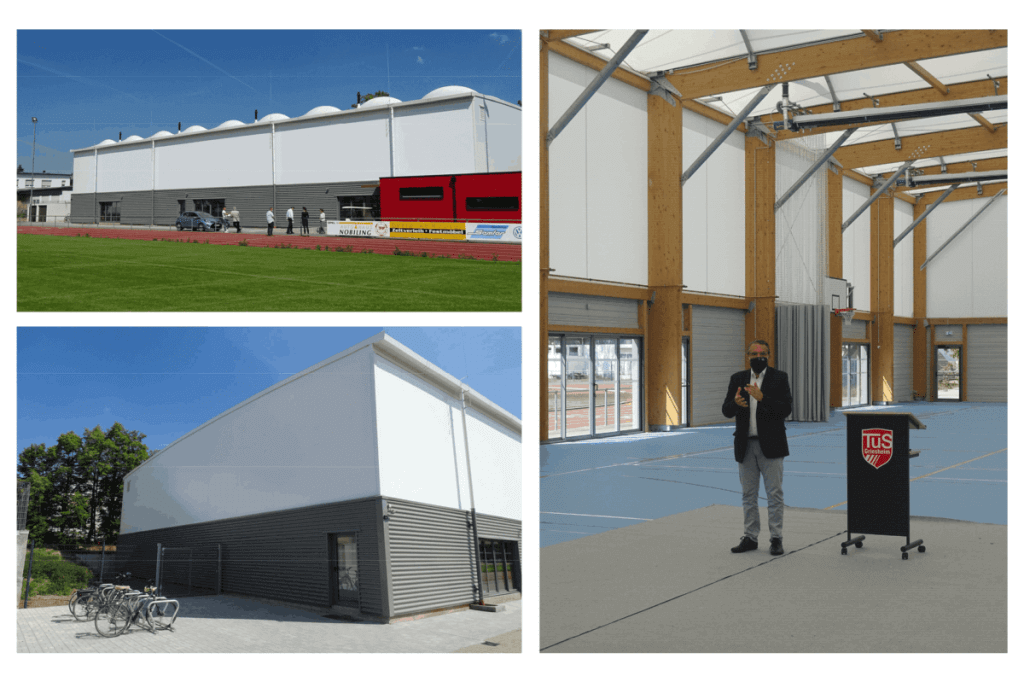

On 27 May 2020, SMC2 inaugurated Germany’s first covered textile membrane gymnasium for the TuS Griesheim association – in partnership with the town of the same name and the Darmstadt-Dieburg district (equivalent to our departments) – in the Frankfurt region. Interview with Dr. Claus Walther, President of TuS Griesheim 1899 e.V:

Dr. Walther, the new sports hall of TuS Griesheim was finally able to open on Wednesday, 27 May 2020. It was a long project in terms of planning, negotiations and implementation, are you satisfied with the result?

We are very satisfied with the visible results. This gym is a real flagship project for our association. In terms of execution details, we see room for improvement in the exterior window sills and interior cable routing. In the end, the gymnasium will have to prove its suitability all year round, in all seasonal weather conditions.

TuS Griesheim, as a non-profit sports association, became the owner of this project. How were you able to bring this project to life and what were the biggest obstacles?

A project of this magnitude can only be implemented in cooperation with competent specialists. In addition to the SMC2 contact persons, this mainly involved a team of architects from the PA+ planning office in Darmstadt, whose tasks included the following activities

- Development of an overall architectural concept including a connecting building between the gymnasium and the sanitary facilities, as well as the conversion and renovation of the latter

- Preparation of the permit documents

- Integration of the SMC2 design into the overall execution design

- General architectural management

- Preparation of cost estimates and calculations

- Design, tendering and awarding of contracts to various trades outside SMC2

- Supervision of all works on site

- Convening and managing site meetings

- Constant communication with the client

- Verification of invoices and transmission to our financial department

- Management of a work schedule and a work log

In addition, a structural engineer was involved in the project to calculate the statics of the retaining wall and foundations, as well as a planner from the PA+ engineering office for the modification of the layout and the BBS engineering office for the specialised design of the electrical, gas and sanitary systems.

Another important requirement for us was the trusting cooperation with all the committees and departments of the association, our bank, the authorities of the town of Griesheim and its mayor, the authorities of the district of Darmstadt-Dieburg, its chairman and first councillor, the competent authorities of the Hessian Ministry of the Interior and Sports, the Hessian Sports Federation, the competent persons of the Darmstadt district council, our association councillor and our caretaker, who is very good with his hands

The almost daily presence of the building owner on the construction site was also a great help. Inspecting all the work and talking to the craftsmen or managers of the companies involved gave us a better understanding of the work processes and enabled us to detect any problems at an early stage. Often, a telephone conversation with the architects, a question to the design specialist or an administration to obtain professional information through the “shortest route” was enough to avoid or solve a problem.

After the decision taken internally by the association in June 2015, based on a financing plan and the participation of the municipality and the district, we had to overcome the following obstacles:

- The modification of the development plan had led to additional costs and a few months of delay.

- The securing of the site with concrete paving stones over a length of 50 m was necessary from the point of view of statics and caused additional costs and several weeks of delay.

- The originally planned screw foundations, which cost less, were not approved. Instead, reinforced concrete foundations had to be built, which were considerably more expensive and time-consuming.

- Since Griesheim is located in seismic zone 1, it was necessary to build a perimeter sill.

- Fire protection requirements increased the costs of renovating the sanitary facilities and changing rooms in the adjacent building.

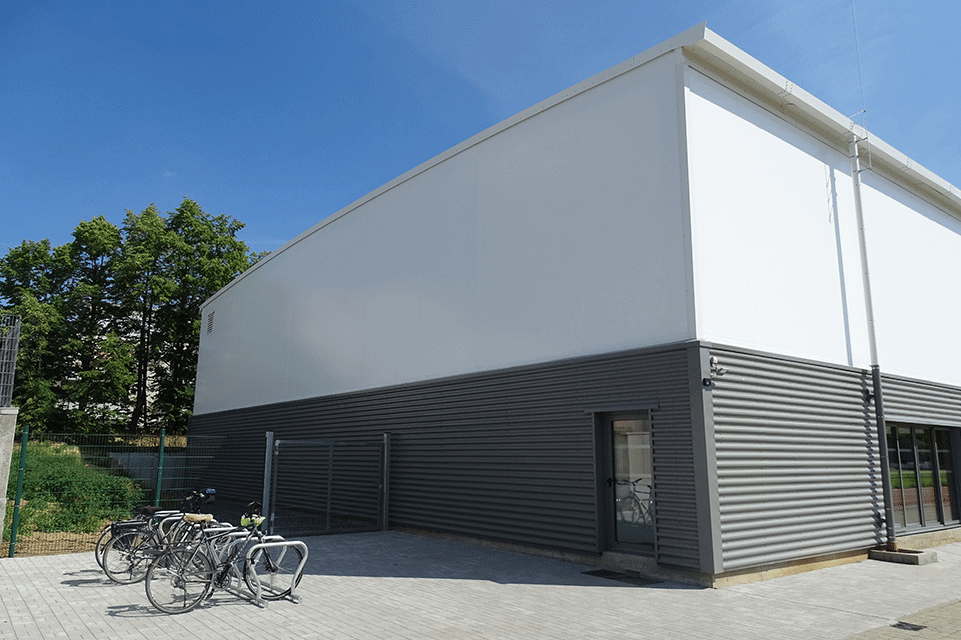

- A building enclosed on all sides serves as the entrance to the gymnasium and as a link to the adjacent sanitary facilities and changing rooms.

Can you give us a brief overview of the construction costs and financing of the project?

The total costs of the project, including the connecting building, the construction of the sanitary facilities and changing rooms and the creation of new parking spaces for cars and bicycles, amount to approximately 1.5 million euros. The district council, as the school authority, and the town of Griesheim each contributed one third of the costs. The operating and maintenance costs were also divided three ways by agreement.

The association also received €200,000 from the Hessian Association’s sports facilities fund, €50,000 from the district’s subsidy and €15,500 from the Hessian Sports Federation. The remaining part of approximately € 235,000 was financed by loans and the association’s own funds.

In contrast to conventional buildings, the new gymnasium consists of a glued laminated timber structure and a textile shell. What is special about this type of construction and what are the advantages and disadvantages?

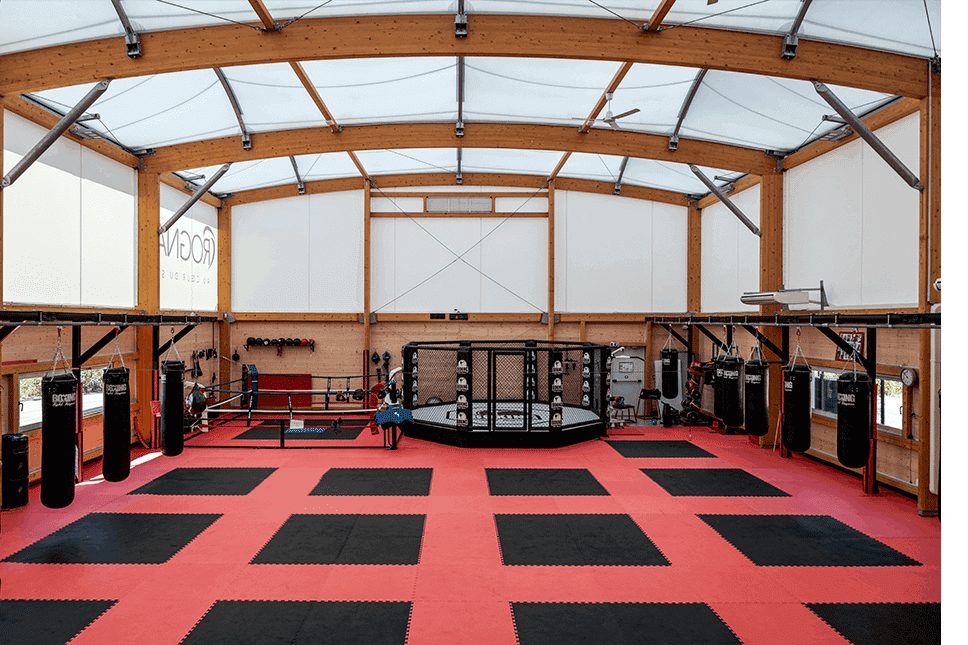

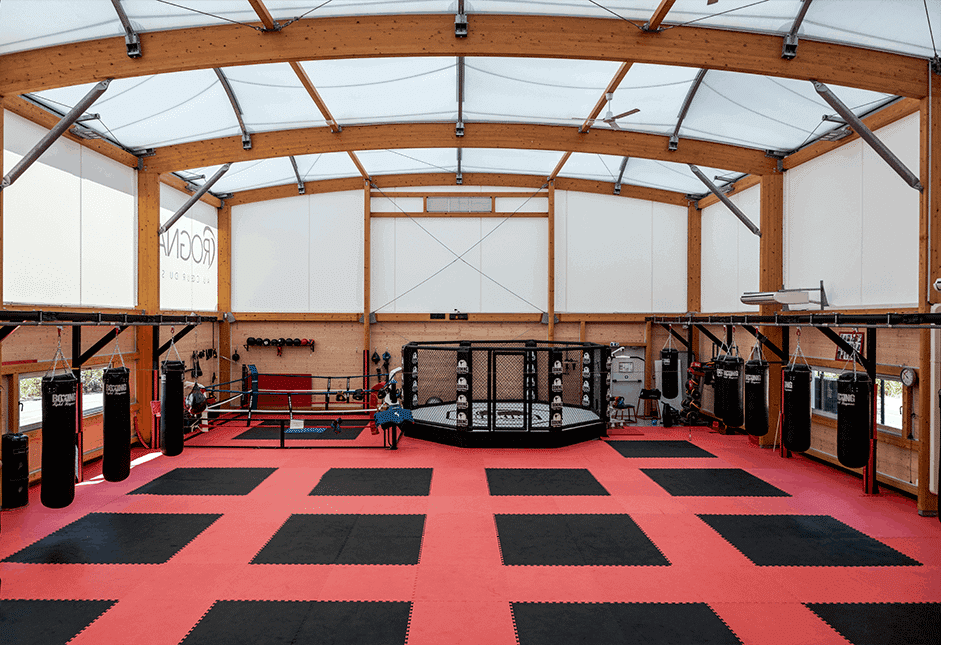

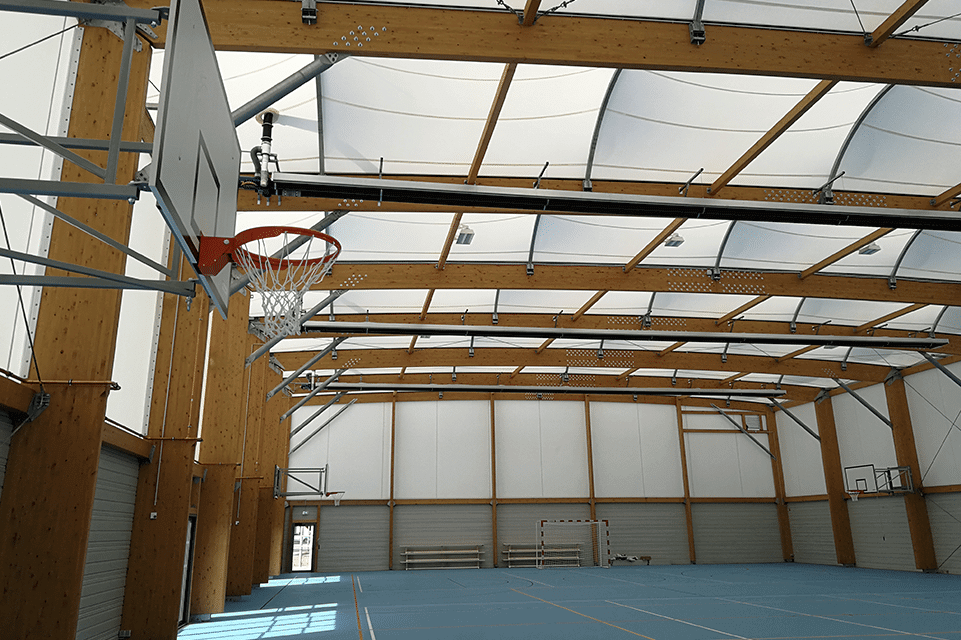

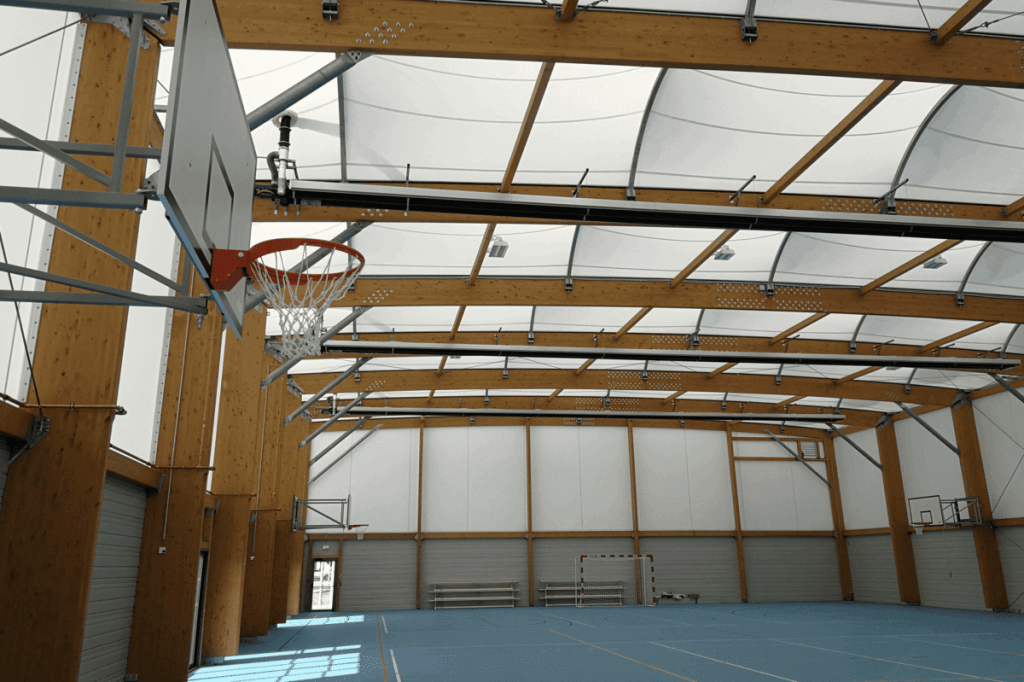

This “light construction” is more economical than a massive construction and is characterised by significantly shorter construction times. The membrane, which allows light to pass through the upper half of the side walls and the roof, promotes natural light in the gymnasium without artificial lighting, even in bad weather and after dark. The wooden structure feels light and contributes to the pleasant and friendly atmosphere one feels in the gym.

The lack of insulation makes the building a “cold hall”. Thanks to the dark gas tubes mounted under the ceiling, the manufacturer guarantees a room temperature of 12 °C in winter, which corresponds to a perceived temperature of 14-16 °C due to radiant heating. A frost sensor also prevents the room temperature from falling below the frost limit. The sports floor is a sandwich floor with an elastic base structure, which is well suited to a cold hall.

In warmer periods of the year, a diagonal ventilation system mounted under the ceiling prevents excessive temperatures due to heat accumulation. In addition, cross ventilation can be generated by opening the sliding windows and the door opposite. An air dehumidification system ensures a pleasant indoor climate even during periods of intensive use of the gymnasium and prevents the formation of drips on the ceiling.

The gym was built by SMC2, a company based in Mornant, France. How did you find out about SMC2 and were you satisfied with the advice they gave you and the implementation?

A member of our management and one of our architects took part in an event organised by the Hessian Sports Federation on the subject of “lightweight gymnasiums” and were particularly convinced by the specific design and lightness of this type of construction!

Overall, we were very satisfied with the advice provided by SMC2. The language barrier was not a problem during the meetings with the French management. We spoke to each other either in one of our two languages or in English. Since one of the two German representatives of SMC2 was always present at important meetings, there were never any misunderstandings, even during complex technical discussions.

The implementation of the project, however, was difficult on several levels. The coordination between the various craftsmen we had commissioned separately to carry out the work processes of the gymnasium builder was not always easy, both in terms of the work itself and in terms of meeting deadlines. In the end, it was the skills of all the participating designers, site managers and companies that made it possible to find suitable solutions in each case, even in very complex cases. In our experience, the question arises as to whether it would not be more advantageous for all those involved to combine several trades and thus reduce the number of companies involved.

The gymnasium is primarily intended for use by schools and associations. What is the planned operating model and which sportsmen and women will find a new playground here?

The gymnasium is designed as a training ground for handball, volleyball, basketball and indoor football. The gym can also be used as a training room for other sports, such as athletics, triathlon or gymnastics. However, apart from mats and benches, no larger sports or gym equipment can be used. The gymnasium can be divided into three parts by means of dividing nets, allowing three groups to train in parallel.

Other local sports associations and schools will also have access to the gym. A planning meeting will redistribute the available slots of all the Griesheim sports halls in the TuS Griesheim area, including our new gym, to the various association departments each year.

One last question: the sports hall at TuS Griesheim is the first in Germany to be built with a textile shell. What is the significance of this flagship project for you, for the association and for the town of Griesheim?

This sports hall is currently a landmark for TuS Griesheim. This innovative, economical and sustainable project makes our association, the town of Griesheim and the district of Darmstadt-Dieburg pioneers in the development of sports facilities. This “flagship project” can serve as a model for the construction of attractive and affordable sports facilities for many other regions, communities and associations. This role is a victory for the project partners.

![[TESTIMONIALS] CLAUS WALTHER, CHAIRMAN OF TuS GRIESHEIM, GERMANY](https://www.smc2-construction.us/wp-content/uploads/2021/10/claus-01-961x640-1.png)

![[temoignage] claus walther, president du tus griesheim, allemagne](https://www.smc2-construction.us/wp-content/uploads/2020/06/claus-02-961x640-1.png)

![[TESTIMONIAL] HELENE BAILLY-MAITRE AND PASCAL AUTRIC, FROM THE URBAN LANDSCAPES DEPARTMENT OF AVIGNON CITY HALL (84)](https://www.smc2-construction.us/wp-content/uploads/2021/10/IMG_4113_recadree-1.jpg)